I. Introduction

The electrical power system is the backbone of modern society, and three-phase dry-type transformers are a critical component within it. This article will delve into the importance, operating principles, application areas, and future development trends of three-phase dry-type transformers.

In today's electrical power systems, three-phase dry-type transformers play a crucial role. They facilitate efficient electricity transmission and adaptation to various power demands by stepping up or stepping down voltage. This article aims to elucidate their fundamental operating principles and their significance within electrical power systems, emphasizing how electromagnetic induction makes voltage transformation possible.

The goal of this article is to provide readers with a comprehensive understanding of the basic knowledge of three-phase dry-type transformers and a clearer insight into their ongoing evolution and prospects in the power industry. Three-phase dry-type transformers play a crucial role in shaping the future of the power industry.

II. Basic Operating Principles of Three-Phase Dry-Type Transformers

The operation of three-phase dry-type transformers involves electromagnetic induction and voltage transformation, which are key to their ability to step up or down voltage.

Three-Phase System: First, we need to understand the basic structure of a three-phase electrical power system. This system comprises three phases of alternating current, with each phase differing by 120 degrees. This three-phase electrical system is commonly used because it provides an efficient and balanced method of power transmission suitable for various electrical applications.

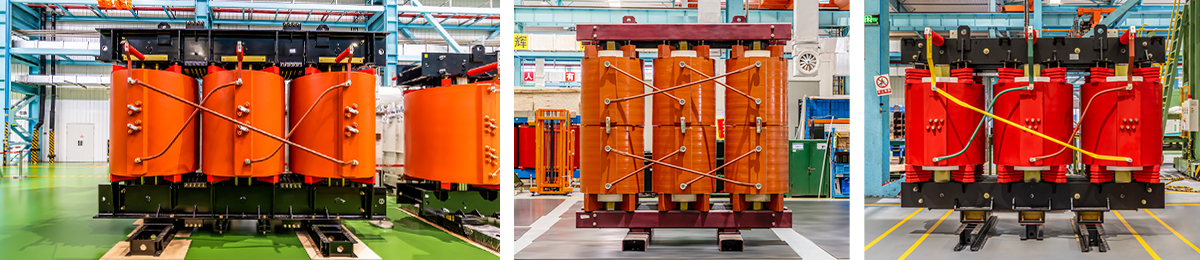

Structure: Three-phase dry-type transformers typically consist of three coils, which include a primary coil, a secondary coil, and a possible neutral coil. The primary coil is usually connected to the power source, while the secondary coil is connected to the load. These coils are wound around a core, typically made of silicon steel laminations, to enhance the electromagnetic induction effect.

Electromagnetic Induction: When alternating current flows through the primary coil, it generates an alternating magnetic field within the transformer's core. This alternating magnetic field, also known as magnetic flux, is a result of the changing current. Due to physical contact between the coils, this alternating magnetic field passes into the secondary coil. According to Faraday's law of electromagnetic induction, an induced electromotive force (EMF) is generated in the secondary coil, leading to a change in voltage. By controlling the ratio of turns between the primary and secondary coils, the transformer can achieve voltage stepping up or stepping down, allowing electrical energy to adapt to different power requirements.

Turns Ratio: The turns ratio is a critical factor in determining the voltage transformation ratio. If the primary coil has more turns than the secondary coil, the output voltage will be higher than the input voltage, achieving voltage stepping up. Conversely, if the secondary coil has more turns than the primary coil, the output voltage will be lower than the input voltage, achieving voltage stepping down.

III. Application Areas of Three-Phase Dry-Type Transformers

Three-phase dry-type transformers play a vital role in various fields, encompassing power transmission and distribution, industry, commerce, construction, and electronic equipment.

Power Transmission and Distribution: Three-phase dry-type transformers are essential in power transmission and distribution. They are typically used for stepping up voltage to reduce energy losses and then for stepping down voltage within distribution networks to accommodate the needs of end-users. These transformers are often referred to as substation transformers, which elevate the voltage generated by power plants to reduce resistive losses during long-distance transmission and then adapt the voltage to the power requirements of cities and industrial facilities.

Industrial Applications: The industrial sector often requires various voltage levels to meet the demands of different equipment and machinery. Three-phase dry-type transformers are used to provide the required voltage for driving industrial equipment, production lines, and machinery. These applications include manufacturing, mining, chemical industries, metal processing, and more.

Commercial and Construction Sectors: Large commercial buildings and industrial parks require reliable power distribution systems to ensure a consistent power supply. Three-phase dry-type transformers are used for power distribution within buildings and commercial facilities to accommodate the voltage needs of various equipment.

Electronic Equipment: Electronic devices often require specific voltage and current to ensure their proper operation. Three-phase dry-type transformers are used to provide the appropriate power supply for computers, communication equipment, medical devices, and other electronic products.

Renewable Energy Systems: With the rise of renewable energy sources such as solar and wind, three-phase dry-type transformers play a crucial role in synchronizing these energy sources with the grid. They help manage the variable power output, ensuring the integration of renewable energy systems with conventional power grids.

In summary, the application areas of three-phase dry-type transformers are diverse, ranging from large-scale power transmission to providing power for small electronic devices. Their flexibility and reliability make them indispensable elements in electrical power systems while offering efficient, stable, and adaptable power solutions across various fields.