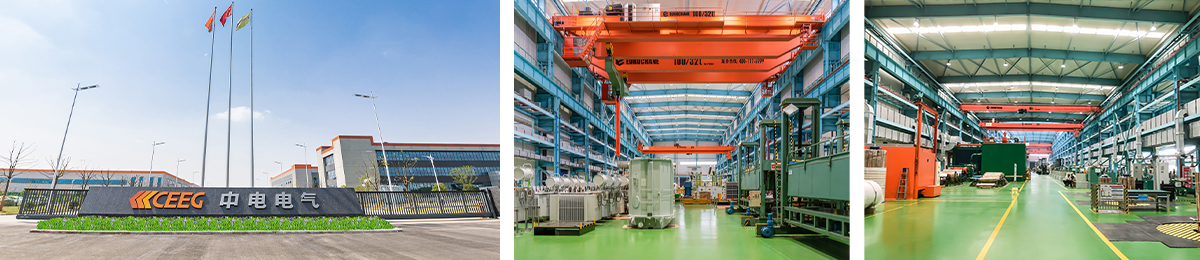

CEEG Yangzhong Factory:

CEEG Transformer Industrial Base in Yangzhong: One of the world's largest dry-type transformer production facility, covering an area of over 40 hectares with a construction area of 180,000 square meters. It employs more than 1000 people and is equipped with a complete set of advanced transformer production and testing equipment, including cutting, vacuum casting, vacuum impregnation, and other facilities. It has an annual production capacity of 30 million kVA for power transformers.

CEEG Yangzhong factory boasts an array of cutting-edge equipment representing a high standard within the industry, including a complete set of shearing machines, fully automated winding machines, robot-operated stacking machines, the German-made Heydrich vacuum casting tank, vacuum impregnation systems, air cushion transport vehicles, a fully enclosed production workshop with a cleanliness level of 100,000, 20-ton vertical winding machines, 10-ton horizontal winding machines, coal-oil gas phase drying equipment, and a 200-ton overhead crane. Pioneering within the sector, the company has also developed and implemented a collaborative design platform for transformers. This innovative platform effectively integrates product data, product development, and production processes.

The main products of CEEG Yangzhong factory include DuPont NOMEX® insulated 10kV non-encapsulated coil dry-type power transformers, DuPont NOMEX® insulated H-class insulation 35kV SG10 series dry-type transformers, rectifier frequency transformers, rectifier excitation transformers, marine (offshore platform) transformers, amorphous alloy dry-type power transformers, H-class dry-type reactors, arc suppression coils. All of the above products have passed the testing of the National Transformer Supervision and Inspection Center and joint appraisal by the State Grid Corporation of China and the State Administration of Machinery Industry.

Over the years, it has engaged in various business activities such as research, development, and production of power equipment products. CEEG has repeatedly been recognized as a "National High-tech Enterprise," "Provincial Key Contract-Abiding and Credit-Respecting Enterprise," "Provincial Clean and Civilized Enterprise," "Comprehensive Quality Management Standard Enterprise," "AAA Credit Enterprise," "Quality Trustworthy Enterprise," "Measurement Qualified Enterprise," and "Green Environmental Protection Enterprise." Two of its high-tech products have been awarded the honor of "National New Product.".

CEEG Binjiang Factory:

CEEG Binjiang Transformer Factory is an integrated entity that encompasses independent research and development, intelligent manufacturing, and smart marketing services. It specializes in the research, production, and provision of products and solutions for amorphous alloy dry-type transformers, mine explosion-proof special transformers, epoxy resin casting dry-type transformers, the full range of transformers up to 220kV oil-immersed transformers, compact substations, and switchgear.

Throughout its rapid growth, we consistently place the safe use of its products as the primary focus of its research and development efforts. Since entering the market, CEEG has rapidly gained the trust of a wide range of users due to its advantages in scale, quality, and service. Its products have been running safely in large coal industry groups such as Shenhua Group, Anhui Tongling Mining Group, Pingdingshan Coal Industry Group, Jincheng Coal Industry Group, and Kailuan Group. Numerous renowned enterprises like China Mobile, China Telecom, Inner Mongolia First Machinery, Inner Mongolia Pingzhuang Energy, and Jialing Motors have established strong partnerships with our company.

In addition to enhancing its existing product line, we continue to develop new projects to enrich its offerings. The new high-capacity products feature a square top with corrugated shell, which combines the advantages of both square and cylindrical shell. In comparison to square shell from other manufacturers, these products exhibit superior heat dissipation and safety performance, aligning perfectly with the company's principles of safety, energy efficiency, and environmental protection. Currently, the company is also working on developing combined switches, feeder switches, and a new 8000KVA project, with the aim of obtaining certification at an early stage.

"Our goal is to establish a famous brand in the industry," and "customer first, user foremost" are the fundamental beliefs we uphold. In the future, CEEG Binjiang Transformer Factory will continue to strive for excellence in the research and development of amorphous alloy products and explosion-proof electrical products. Our commitment is to provide society with safe, reliable, energy-efficient, environmentally friendly, and stable equipment support, offering our users premium services.

CEEG Jurong Factory:

CEEG Jurong Factory was established on May 15, 2015, with a total investment of 250 million RMB. The factory is located within the Rongning Entrepreneurship Park in Jurong City, Zhenjiang, Jiangsu Province. It covers an area of 1.7 hectares and features three modern standardized workshops. The factory houses 10 transformer production lines, equipped with several sets of advanced assembly equipment, achieving an annual output value of 600 million RMB and contributing 40 million RMB in taxes and profits. The factory's business scope includes the design, research and development, manufacturing, and related technical services of power transmission and transformation equipment, as well as the import and export of various commodities and technologies, both under self-operation and agency.

Jurong Factory boasts a top-tier technology research and development team, as well as state-of-the-art experimental and production equipment. Each year, dozens of new technological products are introduced to the market. These new products undergo rigorous testing by authoritative institutions and consistently achieve a technological standard that is domestically advanced. To date, 25 products have passed provincial-level scientific and technological assessments, with 20 of them being recognized as high-tech products. Our research and development efforts have received high praise from various levels of governmental authorities.

In terms of technology adoption, CEEG has consistently adhered to a sound development strategy, actively seeking the introduction and absorption of internationally advanced technologies. The company has collaborated with renowned international enterprises such as DuPont, Siemens, and Schneider Electric, successfully introducing DuPont's "ReliatraN" transformer technology and Schneider's compact substation technology, and collaborations with domestic universities and well-known research institutes have been established across various fields.