Designing a transformer is a complex process that involves consideration of numerous factors to ensure its safe and efficient operation. In addition, compliance with international and local regulations is crucial to guarantee that the transformer meets safety and performance standards. Here are key factors to consider when designing a transformer and the relevant regulations to follow:

Design Factors for Transformers:

Voltage and Frequency: Determine the input and output voltage levels and the operating frequency. These parameters define the transformer's primary function.

Load and Power Rating: Calculate the expected load the transformer will serve and determine the power rating (in kVA or MVA) accordingly.

Core Material and Design: Choose the appropriate core material (e.g., iron or silicon steel) and design to optimize magnetic flux and minimize losses.

Winding Design: Determine the number of turns, conductor size, and winding configuration for both the primary and secondary windings.

Cooling System: Select the cooling method, such as oil-immersed (ONAN), oil-immersed with forced cooling (ONAF), or dry-type (AN).

Insulation Material: Choose the insulation materials for winding and the core to withstand the operating temperature and voltage.

Tap Changers: If required, specify on-load tap changers (OLTC) to adjust the output voltage as needed.

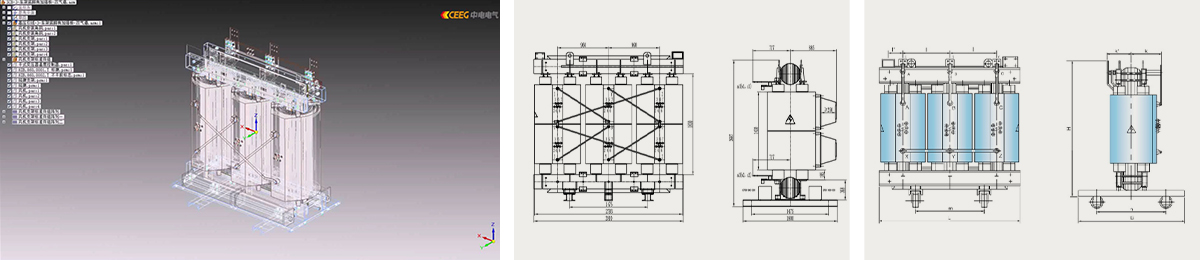

Size and Dimensions: Define the physical dimensions, including the transformer's size, shape, and weight, to ensure compatibility with installation locations.

Efficiency and Losses: Optimize the design for efficiency by minimizing core and winding losses.

Overload and Short-Circuit Capability: Design the transformer to handle temporary overloads and short-circuit conditions safely.

Regulatory Compliance: Ensure the design complies with applicable international and local regulations and standards.

Regulations and Standards:

International Electrotechnical Commission (IEC): The IEC provides international standards for transformers. IEC 60076 is a series of standards that covers power transformers, distribution transformers, and special transformers.

American National Standards Institute (ANSI): In the United States, ANSI standards, such as ANSI C57, define transformer design and performance requirements.

IEEE Standards: The Institute of Electrical and Electronics Engineers (IEEE) offers standards that cover various aspects of transformer design and operation. IEEE C57 standards are widely referenced.

Local Electrical Codes and Regulations: Different countries and regions have their own electrical codes and regulations that transformers must adhere to. These may be based on IEC or ANSI standards but can include specific requirements.

Environmental Regulations: Compliance with environmental regulations related to materials and insulating fluids is essential. For instance, regulations governing the use of PCBs (polychlorinated biphenyls) and the use of eco-friendly insulating fluids.

Safety Standards: Safety standards, such as those outlined by the Occupational Safety and Health Administration (OSHA) in the United States, must be followed to ensure the safety of personnel working with or near transformers.

National Grid Codes: Utilities may have their own specific requirements for transformers, which must be followed for grid connection.

It's essential to collaborate with experienced transformer designers and manufacturers who are well-versed in these regulations and standards to ensure that your transformer design complies with the specific requirements of your project and location. Deviations from the applicable standards may result in non-compliance, safety risks, and potential project delays.