In the wave of energy transition, green hydrogen is emerging as a key force in achieving carbon-neutral goals. However, the economics of green hydrogen projects are influenced by multiple factors. Notably, the volatility and intermittency of wind and solar power pose severe challenges to the safe and stable operation of hydrogen-production equipment, which constrains further industry development.

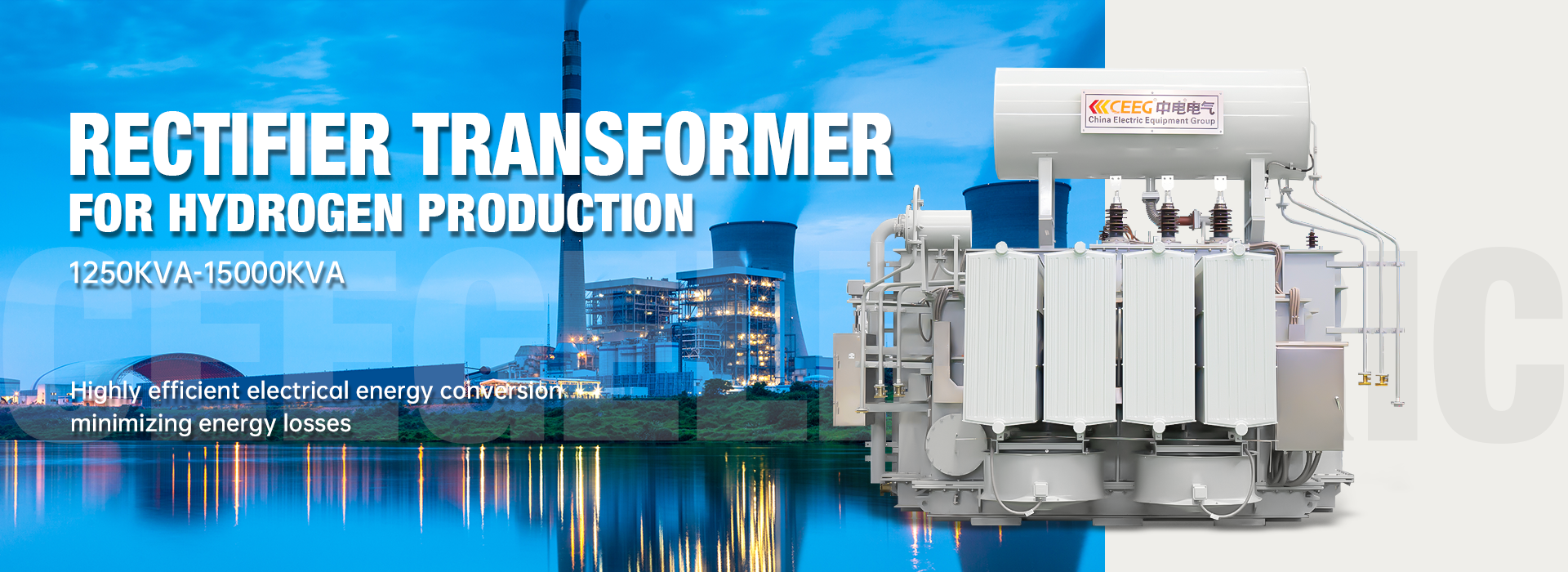

As the core component of a hydrogen production system, CEEG’s rectifier transformer provides a reliable guarantee for green hydrogen production through four core technologies:

Precise Voltage Matching

By precisely adjusting the input AC voltage, the transformer converts it to the most suitable DC voltage level for the electrolyzer, ensuring the equipment always operates at optimal conditions.

High-Efficiency Energy Conversion

Using advanced design and high-quality materials, the transformer significantly improves energy conversion efficiency, minimizing energy losses and effectively reducing operational costs.

Fluctuation Mitigation Capability

The transformer possesses excellent shock resistance and overload capacity, able to buffer the power fluctuations from wind and solar generation, supplying the electrolyzer with a smooth and stable DC power source.

Power Quality Optimization

By employing advanced rectification technology (e.g. multi-pulse rectification), harmonics and interference from the input source are suppressed at the source, delivering high-quality DC output. This ensures electrical safety and stable operation of the entire hydrogen production system.

For large-scale hydrogen production via water electrolysis at 1000 m³/h, there are currently two mainstream rectification design schemes:

Multi-pulse three-phase thyristor bridge rectification system.

Three-phase bridge PWM rectification + DC/DC chopper system.

Among them, the multi-pulse thyristor rectification system — widely accepted for its adaptability to various electrolyzer parameters, mature and reliable technology, lower investment cost, and small footprint — is especially suitable for green hydrogen production scenarios powered by unstable renewable sources such as photovoltaics (PV) or wind.

CEEG is a professional transformer manufacturer! Our production base covers an area of more than 600 acres (40 hectares) with extensive facilities and a total construction area of 180,000 square meters. We have a professional team of more than 1,000 employees. We have advanced transformer production and testing equipment here to ensure that we provide customers with high-quality power transformer products.

CEEG is a professional transformer manufacturer! Our production base covers an area of more than 600 acres (40 hectares) with extensive facilities and a total construction area of 180,000 square meters. We have a professional team of more than 1,000 employees. We have advanced transformer production and testing equipment here to ensure that we provide customers with high-quality power transformer products.

We boast an array of cutting-edge equipment representing a high standard within the industry, including a complete set of shearing machines, fully automated winding machines, robot-operated stacking machines, the Hedrch Vacuum Casting Equipment, vacuum impregnation systems, air cushion transport vehicles, a fully enclosed production workshop with a cleanliness level of 100,000, 20-ton vertical winding machines, 10-ton horizontal winding machines, coal-oil gas phase drying equipment, and a 200-ton overhead crane. We adopt the latest technology and processes to ensure our products comply with international standards and customer needs.

We have a strong production capacity of 30 million kVA power transformers annually. This means we can cater to all sizes and types of power transformer needs, from small applications to large energy projects. No matter what specifications our customers require, we deliver them on time and support them with high quality and reliability.

.jpg)