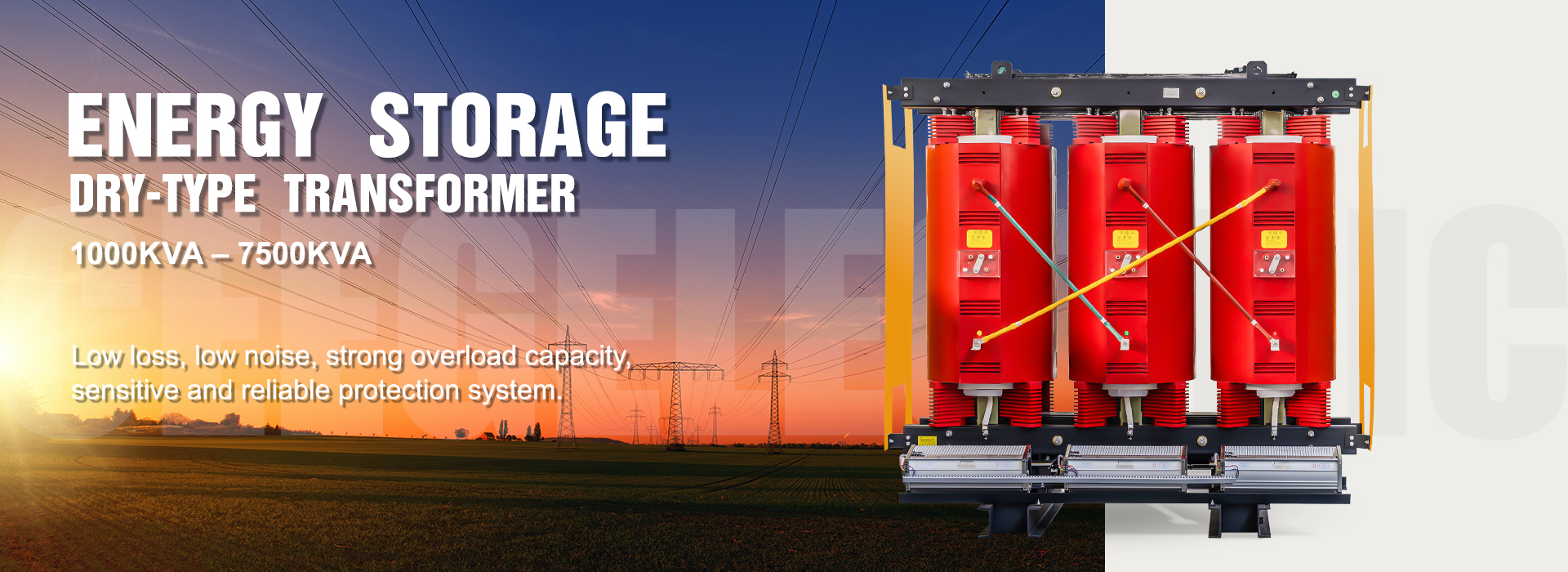

Low Loss: No-load losses are 20% lower than national standards, and load losses are 10% lower, meeting national energy efficiency requirements.

Low Noise, Low Partial Discharge: Noise levels are 10dB lower than national standards, and partial discharge is less than 5pC.

Three Special Characteristics Tests: The product passes F1, C2, and E2 level combustion environment and thermal shock tests. It is fire-resistant and can be directly installed in the load center.

Strong Overload Capacity: It uses H-class (180°C) insulation materials and is designed for a temperature rise of F-class (100K). The insulation system has a large margin, ensuring a strong overload capacity.

Sensitive and Reliable Protection System: Equipped with a three-phase temperature-controlled protection system that can be monitored remotely. It has a forced air cooling system to meet specific environmental requirements.

*Compliance with Standards:

GB/T1094.1 Power Transformers - Part 1: General

GB/T1094.3 Power Transformers - Part 3: Insulation Levels, Insulation Tests, and External Insulation Air Gaps

GB/T 1094.11 Power Transformers - Part 11: Dry-Type Transformers

GB/T 10228 Technical Parameters and Requirements for Dry-Type Transformers

GB 20052 Limit Values and Efficiency Levels for Power Transformers.

Our transformer production facility covers an area of over 40 hectares with a construction area of 180,000 square meters. It employs more than 1000 people and is equipped with a complete set of advanced transformer production and testing equipment, including cutting, vacuum casting, vacuum impregnation, and other facilities. It has an annual production capacity of 30 million kVA for power transformers. We boast an array of cutting-edge equipment representing a high standard within the industry, including a complete set of shearing machines, fully automated winding machines, robot-operated stacking machines, the Hedrch Vacuum Casting Equipment, vacuum impregnation systems, air cushion transport vehicles, a fully enclosed production workshop with a cleanliness level of 100,000, 20-ton vertical winding machines, 10-ton horizontal winding machines, coal-oil gas phase drying equipment, and a 200-ton overhead crane.

Our transformer production facility covers an area of over 40 hectares with a construction area of 180,000 square meters. It employs more than 1000 people and is equipped with a complete set of advanced transformer production and testing equipment, including cutting, vacuum casting, vacuum impregnation, and other facilities. It has an annual production capacity of 30 million kVA for power transformers. We boast an array of cutting-edge equipment representing a high standard within the industry, including a complete set of shearing machines, fully automated winding machines, robot-operated stacking machines, the Hedrch Vacuum Casting Equipment, vacuum impregnation systems, air cushion transport vehicles, a fully enclosed production workshop with a cleanliness level of 100,000, 20-ton vertical winding machines, 10-ton horizontal winding machines, coal-oil gas phase drying equipment, and a 200-ton overhead crane.