With the development of amorphous metal in the 1970s, it became widely used in 1990 as a high-energy-saving material for the transformer industry. Currently, over 1 million tonnes of amorphous metal-type transformers have been connected to the grid worldwide. The longest proven safe and most reliable transformer has been running for more than 30 years, and it still performs satisfactorily in the power industry.

The energy saving is huge and it shall be the new era products in the power industry.

Amorphous Metal Replacing Silicone Steel

Amorphous metal is a metallic material with a disordered atomic-scale structure.

Amorphous metal is non-crystalline, the alloys of boron, silicon, phosphorus, and other glassformers with magnetic metals (iron, cobalt, nickel) are magnetic, with low coercivity and high electrical resistance. The high resistance leads to low losses by eddy currents when subjected to alternating magnetic fields, a property useful e.g. transformer magnetic cores.

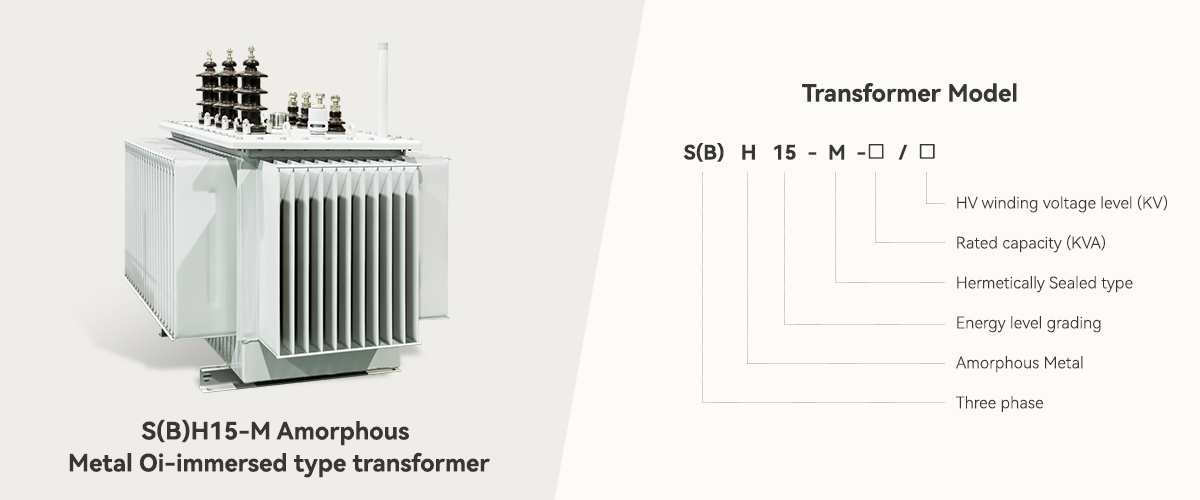

Feature of Amorphous Core: Three phases three columns, self-invention by CEEG, which received many patents, low iron loss, temperature rise and noise level, transformer dimension small.

1) All raw materials are supplied by Hitachi Metals with iron loss of less than 70-80% of the standard silicon steel.

2) The company has special treatment, procedure, and manufacturer processes, which have patent numbers: 200810238258.6,20082015857.5,200820215858.X, 200820215812.8, 200820215814.7.

3) The core structure is clean and strong, which is not influenced by the movement created during transportation.

4) The three-column structure can withstand high-level harmonics. At Y-connection, the transformer can resist the 3rd harmonic in the network.

1. Reliability of Insulation Technology

1. Reliability of Insulation Technology

Our research spans from initial two-dimensional electric field simulations, three-dimensional electric field measurements, and impact characteristic measurements to later-stage theoretical analysis and simulated experiments on the main insulation, longitudinal insulation, end insulation, insulation of leads, and coil withstand voltage characteristics of transformers. Through years of verification using various methods, we ensure the reliability of transformer insulation.

2. Calculation of leakage magnetic field and reduction of stray loss

Dedicate specialized efforts to calculating and measuring transformer leakage magnetic fields. The research includes shielding structures for leakage magnetic fields, calculations for transformer dynamics and thermal stability, and improvements in transformer dynamic and thermal stability to guarantee accurate calculations and reduce stray losses, enhancing transformer dynamic stability.

3. Precise Analysis of Coil Temperature Fields

Collaborating with numerous domestic universities, we jointly developed programs for calculating coil temperature fields. These programs calculate loss distribution in coils, including resistive losses, eddy current losses in different directions, and circulating losses between parallel conductors, as well as flow field cooling conditions. This enables the accurate calculation of coil temperature distribution and hotspot temperature rises, allowing us to take measures to control hotspot temperature effectively rises that impact transformer lifespan.

4. Reducing Local Discharge in Transformers

Electric field strengths at various locations have undergone numerical analysis during the design phase and have been strictly controlled. Additionally, compliance with manufacturing quality, the reliability of processing methods, and the reasonableness of operating techniques effectively control local discharges in transformers.

CEEG is a professional transformer manufacturer!